In 2022, the air compressor market had a value of more than $11 billion — and it’s expected to grow even more. From these statistics, it is clear that rotary screw compressors are a popular air compression option. As the name suggests, a rotary screw air compressor uses rotating screws to compress air. These versatile compressors can be used across various industries to fulfill different roles. They’re reliable and durable, making them the preferred choice for many industry professionals.

Rotary air compressors are designed to help businesses by increasing their productivity and improving the effectiveness of their processes. Knowing how rotary air compressors work, what their purpose is and what benefits they offer can help you better understand how they may fit into your operation.

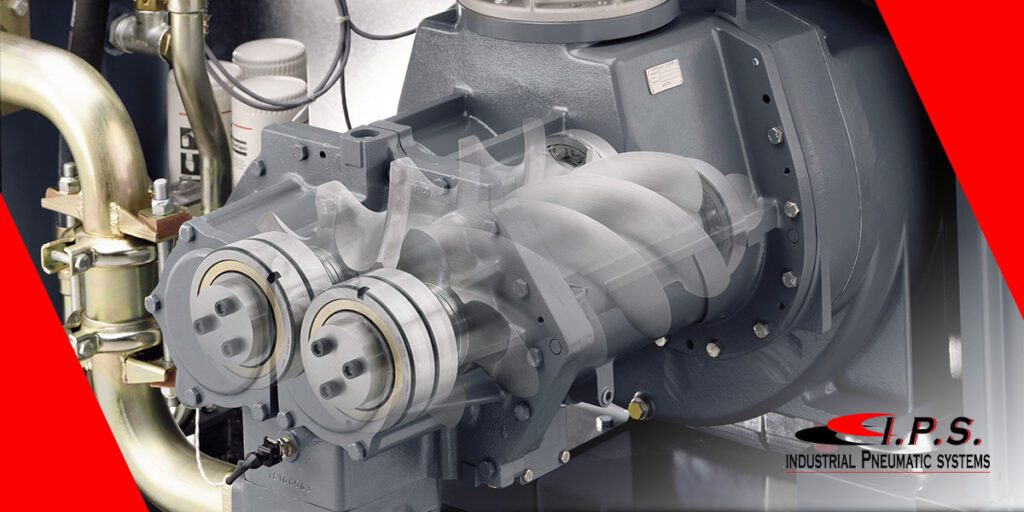

What Are the Operating Principles of Rotary Screw Air Compressors?

Rotary screw compressors use twin screws, with the male and female rotors turning in different directions to allow air to draw between them. They then compress air in the following way:

- Air progresses alongside the rotors, which decreases the space between them and their housing.

- The electric motor then uses energy to create power, which generates air compression.

- A filter removes contaminants from the air to maintain quality.

- The air is then delivered to the pneumatic system.

- The compressed air is displaced to the outlet, ready to be used for various applications.

What Are the Benefits of Rotary Screw Compressors?

With multiple air compressors on the market, it’s important to understand what they offer so that you can decide whether they’re a good investment and if they meet your requirements.

Some of the most significant benefits of getting a rotary screw gas compressor are:

- Continuous operation and efficiency: These compressors are designed to handle a heavy workload. A high-quality rotary screw air compressor can run nonstop without any problems. Their reliable performance and capacity for continuous use make rotary screw air compressors ideal for businesses that require machinery to run 24/7.

- Low-maintenance requirements: Present-day rotary screw systems are much more effective than in the past and have fewer parts than previous designs. Because of this, they require less maintenance.

- Quiet operation: When compared to other compressors, rotary screw compressors are much quieter. Their low sound levels make them ideal for use in workplaces.

- Energy efficiency and longevity: Rotary screws produce less heat than some other compressors on the market. Their lessened heat production, combined with the fact that they consume less oil than most compressors, means that they are energy-efficient and can last a long time.

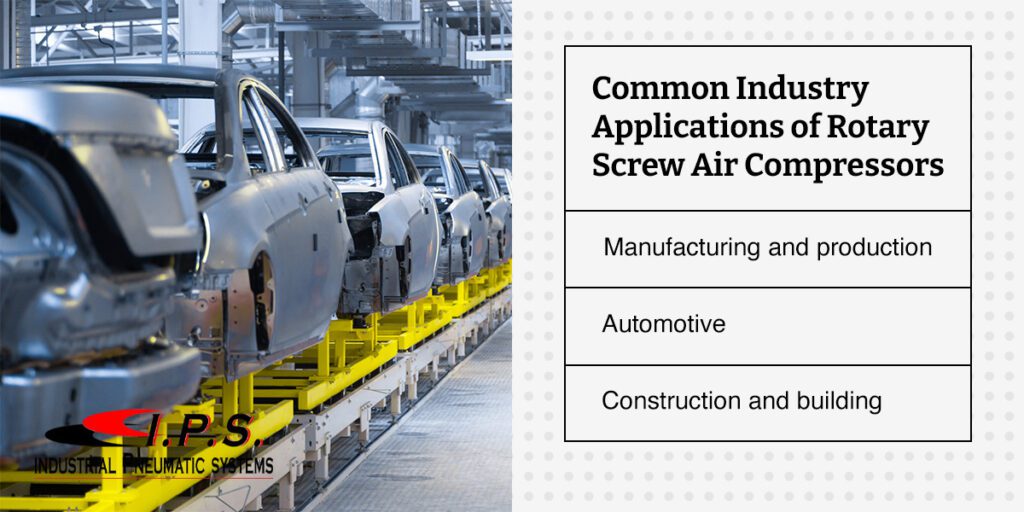

Common Industry Applications of Rotary Screw Air Compressors

Because rotary screw air compressors are so versatile, they are popular in a wide range of industries. Three of the most popular sectors that utilize rotary screw air compressors in their processes include:

- Manufacturing and production: Manufacturing companies often use rotary screw compressors in their assembly lines and production facilities. These screws play an essential role in maintaining operational efficiency.

- Automotive: Rotary screw compressors benefit automotive workshops as they can play a role in the painting and assembly of automotive parts.

- Construction and building: Since rotary screw air compressors are used in power tools and heavy machinery, they are instrumental in construction and building processes, especially since they can withstand harsh environments.

Are Rotary Screw Compressors Suitable for Your Industry?

If you are in the manufacturing, automotive or construction space, you can likely benefit from rotary screw air compressors. However, their purpose isn’t limited to only these industries. Depending on the size and type of rotary screw compressor you get, you can apply this tool in many ways, making it great for various industries.

Smaller compressors are ideal for remote areas where you need to easily and efficiently install a compressor, whereas bigger ones are perfect for large industries. You can also choose between oil-lubricated compressors versus oil-free ones, widening your options even more. Oil-injected compressors are used for industries that use gas refrigeration, while an oil-free option is better for areas where air quality is a priority.

The use of air compressors in the pharmaceutical and food industries is expected to grow over the next few years. Even if you don’t currently use air compressors, it could be worth considering. If you need to determine how rotary air compressors can help your business or need assistance determining if they’re the right fit for you, contact an air compressor installation company.

Why Choose Industrial Pneumatic Systems for Your Compressor Needs?

At Industrial Pneumatic Systems, we pride ourselves on offering high-quality air compressors at affordable prices. We have various rotary screw compressors to meet your needs, and our advanced experience places us in the position to help you with your compressor needs.

At Industrial Pneumatic Systems, we have a few things that set us apart from our competitors. Some of the things we offer include:

- Full-service solutions: Our full-service repair includes systems, parts and services. We also service and repair all brands of compressed air systems and offer system analyses and air audits. Our various services mean you can get everything you need for your compressors in one convenient place.

- Expertise: We have over a decade of experience in the compressed air and vacuum industry, and our employees are knowledgeable about all things air compressor-related. Our expertise allows us to give you the service you deserve.

- Commitment to our customers: We’ve built our business on customer satisfaction and are highly committed to our customers. From technical support to emergency services, our growing team is here to help you with whatever support you may need.

- Quality: Good air compressors should function well and last long, and that’s precisely why we sell high-quality air compressors.

- Trust: There’s a reason so many industries trust us. Our exceptional service, combined with our experience, customer service and quality products, makes us the go-to for many industry experts, and we can offer you the same experience.

Take the Next Step in Your Air Compression Journey

Based on the advantages of rotary screw compressors and their application in so many industries, you may be ready to take the next step and invest in your own air compressor. Whether you want more information on a specific rotary screw compressor for sale or you already have one and it needs servicing, Industrial Pneumatic Systems can assist you every step of the way. Have a look at our products to see our options.

When you’re ready to get an air compressor, we’re here to help. Contact us today to learn more!